| Sign In | Join Free | My gastesters.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My gastesters.com |

|

Brand Name : IBON

Model Number : IB1625C

Place of Origin : DongGuan, China

MOQ : 1

Payment Terms : ,T/T

Supply Ability : 30 sets per month

Delivery Time : 15~25days

Packaging Details : Wooden Case

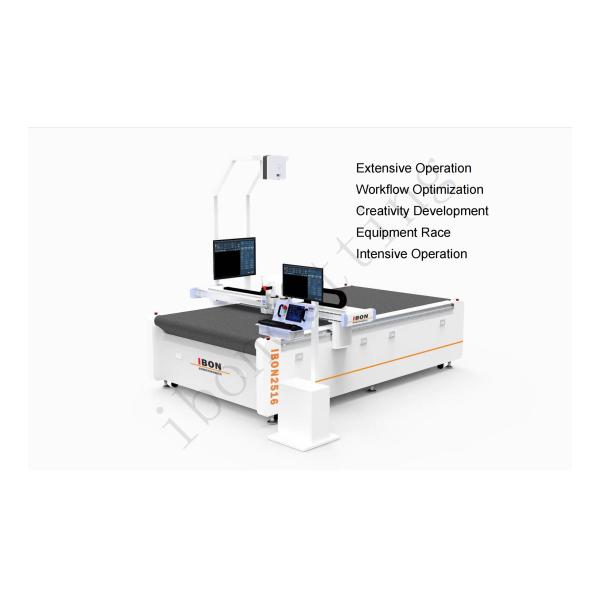

Product name : Automatic Foam Cutting Machine

Customization : Available

After-sales Service : Three Year Warranty

Warranty : Lifetime Free Upgrade Lifelong Free Service

Cutting Materials : Gasket,PVC,EPE,Rubber,Foam,Sponge,Carbon Fiber,Composite Material.,etc.

Max.Cutting Thickness : 60MM (According to the material)

Cutting Range : 1600mmX2500mm

Automatic Leather Defect Identification & Smart Nesting

The IB1625 Precision Genuine Leather Cutter is engineered for premium leather production, offering superior cutting accuracy for earphone cases, footwear, handbags, small leather goods, and upholstery components. Equipped with advanced vision technology, the system can automatically detect leather defects, classify usable areas, and perform intelligent automatic nesting to maximize material utilization.

High-Precision Cutting

Delivers clean, accurate cuts for genuine leather, synthetic leather, microfibers, PU, and other soft materials.

Automatic Leather Defect Recognition

Built-in HD scanning system identifies scars, holes, wrinkles, and color variations, ensuring only high-quality zones are used.

Smart Automatic Nesting

Optimizes pattern layout to reduce waste and increase yield—ideal for high-volume leather production.

Perfect for Multi-Industry Use

Designed for earphone cases, leather shoes, bags, wallets, mobile covers, and more.

Consistent & Efficient Production

Improves quality, reduces manual labor, and delivers stable performance for both sampling and mass production.

Maximize leather utilization

Reduce human inspection errors

Increase cutting precision and consistency

Boost production speed and overall efficiency

Suitable for high-end leather manufacturing

Automated Leather Nesting Machine for Small Accessories

AI VisionScan Leather Nesting System

Leading AI leather nesting algorithm codes increase leather utilization rate, provide user-friendly experience, and unlock the full value of every inch of leather.

AI automatic nesting function.

Users can manually intervene in the layout results.

Equipped with defect detection and utilization functions.

Supports partitioning, pairing, and simultaneous nesting of multiple leather pieces.

Supports automatic counting function and can be combined with oscillating knife series systems and laser cutting systems.

Advantages:

Die-less cutting offers the ability to work with a variety of different materials and thicknesses, rapidly making part/SKU changes all on the same machine. In addition to being more economical, there are a multitude of other advantages in terms of:

Efficiency

Flexibility

Accuracy

Speed

Less floor space required

Features:

High Precision: The electric oscillating cutting tool ensures smooth, clean edges, making it ideal for creating high-quality ceiling panels.

No Need for Molds: Our CNC cutting solution eliminates the need for costly molds, providing flexibility and reducing production costs, especially for customized designs.

Efficient Production: The automated process significantly increases production efficiency, rapidly completing even complex cutting patterns. Dust-Free Processing: Unlike traditional cutting methods, the oscillating knife ensures a dust-free environment, critical for maintaining a clean workspace.

Multi-Function Capability: The machine can be configured with cutting and grooving tools, allowing it to complete multiple processing tasks in a single operation, further enhancing efficiency and versatility. This cutting method is perfect for businesses looking to streamline their production of acoustic ceiling panels with superior quality, speed, and versatility.

| Machine Parameters: Automatic Feeding Model NO. 1625 | |||||

| Model | IB-A2-1625Automatic Feeding | ||||

| Cutting Range | 1600mmX2500mm | ||||

| Size | Approximate Size 2200mmX3500mm | ||||

| Max. Cutting Speed | 60-2200mm/s | ||||

| Minimum Cutting Circle Diameter | 5mm | ||||

| Input Buffer | 128MB | ||||

| Max.Cutting Thickness | 60MM (According to the material) | ||||

| Cutting Accuracy | +-0.1mm | ||||

| Repeat Accuracy | +-0.1mm | ||||

Cutting Effects:

FAQ

1. Can it be used for the fabric industry?

Yes, our digital cutting machines can be widely used in fabric, cloth, pu leather and other flexible material industry.

2. What's the mas thickness of ur pneumatic cutting tool can cut?

Our digital cutting table can be installed with the pneumatic cutting tool, and this tool can cut up to 70 mm;

3. The work you wanna handle with this digital cutting machine(Engraving ?Cutting ?Or others?)

The digital cutting machines can do the job of cutting, creasing and marking.

4. Do you have the manual of fabric cutting machines?

Yes,we can provide manual,CD software and video to help you operate the machine expertly.

5. If we do not know how to use the cnc cutting machine,can you teach us?

Yes ,of course. We can offer you free training, and engineers available to service machinery training overseas if you would like to offer them business expenditure.

6.How about your guarantee period for the digital cutting table?

Twelve months for the whole machine and 3 months for consumables including laser tube, lens and mirrors.

Certificate:

Packaging

|

|

IB1625G Precision CNC Leather Cutter with 1600mmX2500mm Cutting Range and 60MM Max Thickness for Genuine Leather Images |